Ceramic Materials & Products Testing & Analysis

Ceramics are everywhere. Developing the next generation of products and getting them to market, quickly and cost-effectively is key to Lucideon. Not only does Lucideon test materials and products for raw material assessment, product development and quality control, but also, we test for product and material evaluation conformity, safety, legislative, and environmental impact purposes. This is to ensure that products are fit-for-purpose and ranges across the traditional and technical ceramics industries.

We test at all stages of the product lifecycle from prototyping to during processing and in use.

Testing can be divided into:

- chemical analysis from bulk composition to trace analyses down to parts per trillion

- mineralogical and microstructural analysis for determination of crystal structure and phase determination at nanoscale. Doping and coating composition can be determined

- surface analysis to look at staining, contamination, depth profiling, roughness and provide photos of topography

- rheological assessment – determination of shear rates

- porosity testing

- high temperature and thermomechanical tests

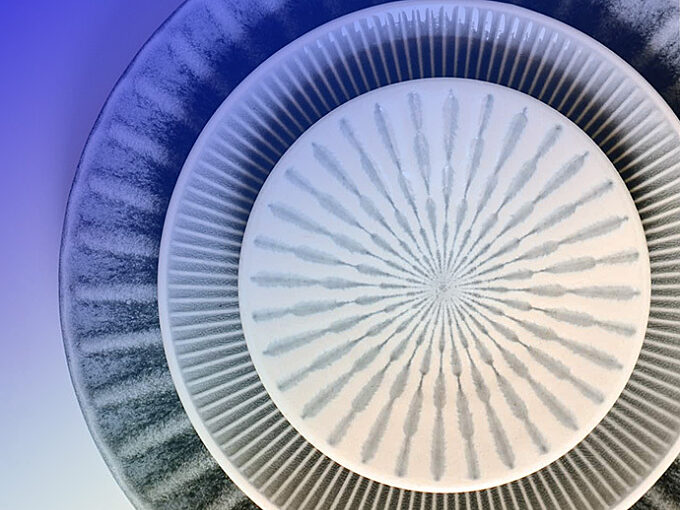

- BS: EN specification for traditional ceramics, glassware, cookware etc. Electrical breakdown and capacitance testing up to tera ohm range

We also offer determination of physical properties such as grading, density, porosity, strength, rheology, mechanical, electrical and thermal properties and microstructure to study product failure or defects, failure mechanisms, inclusions, grain size and bonding structures, surface analysis, degradation and contaminants.

Typical work involves the analysis and testing of tiles, tableware, construction products, sanitaryware, refractories, raw materials and advanced ceramics.

Typical applications

- characterisation of doped cell structures for electro ceramics

- measurement of hard coating composition and structure e.g. carbides, nitrides on machine tools

- characterization of hydroxyapatite coatings on medical implant materials

- thermal shock failure in tableware, for example: product recalls

- identification of processing issues in sol-gel transition, forming and raw materials surfactant appraisal

- contamination assessment

- corrosion products and corroded materials

White Papers