Regulatory Strategy & Testing - Orthopaedic & Medical Implants

Lucideon supplies regulatory testing and rationale support for the orthopaedics industry. Our full range of complementary tests, method development, and validation are designed to support Original Equipment Manufacturers (OEMs) in producing their regulatory documentation ready for successful submission.

Some examples of what we can do:

- Develop and write the testing protocols for regulatory submissions

- Compare dossiers from one regulatory submission against the requirements of another

- Wear testing of hips, knees, ankles, shoulders, wrists, and elbows

- Static and fatigue mechanical testing of all orthopaedic products

- Validate hydroxyapatite (HA) coatings against the FDA (Food and Drug Administration) guidance

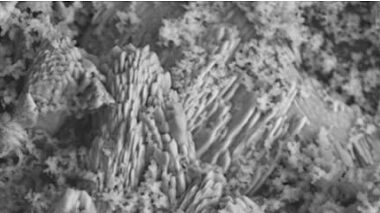

- Evaluation of porous metallic surfaces including additive manufacture (i.e., 3D printing)

- Establishing and validating cleaning processes

- Biocompatibility testing

- Characterisation of new materials for benchmarking

- Cleaning and sterilisation validations for reusable devices and instruments

- Establishing substantial equivalence

Our experts have a depth and breadth of experience of the requirements demanded by the FDA. If you are preparing for 510(k) submission, then get in touch and discuss how we can support with third party testing, validation, and troubleshooting. We find that FDA standards are the most sought-after tests for orthopaedic devices, but we also work to other standards when needed.

Having the rationale, and not just the numbers, means you will be better prepared for any push backs from the FDA or other regulatory bodies.

Lucideon's ISO 17025-accredited laboratories, and expertise in chemical, physical, microstructural, microbiological and surface analysis, ensures your orthopaedic implants are ready for regulatory submission.

Biocompatibility testing

Part of our suite of tests for regulatory strategy is biocompatibility testing which determines if your product is safe for contact with, or implantation into, the body, as necessary for regulatory approval. It is also an important part of medical device testing for regulatory pathways and agencies (e.g., FDA, 510k, PMDA, etc.).

At Lucideon we have extensive experience in biocompatibility testing, developing, and validating methods for your products. We perform a wide range of in-vitro chemical testing and analysis, enabling us to prove that your processes and products are safe for in-vivo trials according to standards, and identify the cause of any contamination if present. We test to ISO 10993 – an essential requirement for regulatory submission.

We are official partners with Bibra, the toxicology advice and consultancy experts. Our partnership means we provide a complete service offering, spanning the expertise of Lucideon and Bibra, with the convenience and visibility of just one program operator. With our collaboration we can also supply toxicology hazard and risk assessments,

We analyse and interpret the in-depth data that we produce to offer you a full support service in all your testing with us. Should post-market failures occur, caused by biocompatibility issues, we can help to solve those failures quickly and effectively through our troubleshooting team and biocompatibility experts.

Animal testing is not offered in our portfolio of biocompatibility services.