Ceramics Industry Services

Ceramics are the core of our business, in all their shapes, forms and applications. We are the development partner you can trust.

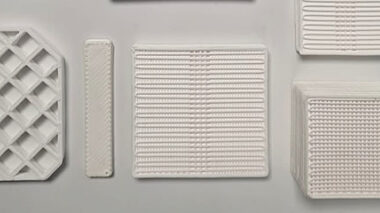

Our pilot-scale manufacturing facilities excel at: raw materials sourcing and refining, powder processing, forming, drying, and sintering. The facilities at our disposal are operated by a team of ceramics experts, supported by our state-of-the-art comprehensive analytical capabilities and our disruptive technologies. We also have access to The AMRICC Centre as one of the founding investors of AMRICC (Applied Materials Research, Innovation & Commercialisation Company). To find out more about how our technologies are changing how we make and use ceramics, visit our Technologies section.

Contact us to find out how we can change the way you view ceramics and the areas they can be used in, for example:

- Technical ceramics

- Electronics

- Medical ceramics

- Tableware

- Refractories

- Coatings (e.g., thermal barrier coatings)

- Tiles

- Sanitaryware

- Nuclear energy

Testing & characterisation

» Testing & characterisation services for the ceramics industry

White Papers